Airbus Introduces More Robots to Assembly Lines

October 1, 2019

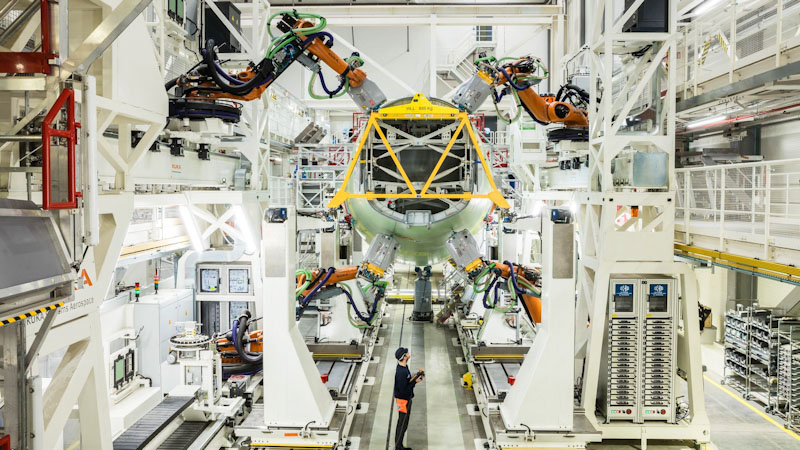

Airbus has inaugurated a new automated fuselage assembly line for the A320 family of aircraft at its Hamburg factory in Germany.

The new facility uses 20 robots to assemble fuselage sections for the A321LR jet. It features automated positioning using laser measurement and an associated digital data acquisition system.

“This new fuselage structure assembly line is an essential enabler for the A320 family ramp-up,” Airbus COO Michael Schoellhorn said. “Increasing the level of automation and robotics enables faster, more efficient manufacturing while keeping our prime focus on quality.”

The new system’s initial assembly section uses eight robots to drill and counter-sink 1,100 to 2,400 holes per longitudinal joint. The second production step involves 12 robots operating on seven axes, to combine central and aft fuselage sections with the tail to form one component.

Schoellhorn said Airbus is taking the necessary steps “to ensure our production system can match the excellence of our products and that we are able to satisfy our customers’ needs for our single-aisle aircraft. We now need to deliver in line with our commitments made to customers while ensuring overall competitiveness.”

Airbus Hamburg is responsible for joining single fuselage shells into sections, and the final assembly of single sections to aircraft fuselages.

The sections are then equipped with electrical and mechanical systems before delivery to the final assembly lines in France, Germany, China and the United States.